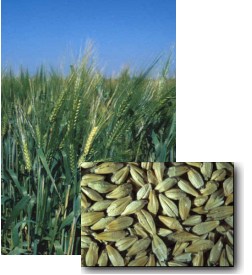

Barley Production and Management

|

Field Selection

Select fields with good drainage, sandy loam to heavy clay soil textures.

For malting, seed or food uses, avoid fields where volunteers of other varieties of barley, other cereals and large oilseeds such as sunflowers may be a problem. Avoid fields that had cereal crops in the previous year to reduce disease pressure and optimize yields.

Variety Information

Performance Testing

Variety Performance, Acreage, Seeding Date And Crop Rotation Effects On Yield

- Manitoba Management Plus Program by Manitoba Agricultural Services Corporation (MASC)

Seeding Barley

Treatments

Loose or surface-borne smuts, leaf stripe, seedling blight and root rot diseases can be controlled by fungicide seed treatment. Consult Manitoba Agriculture's Guide to Field Crop Protection for specific information on individual seed treatments.

Dates

May 1 to May 31. On average, the best quality and the highest yields are obtained from barley that is sown early.

Rates

1.25 to 2.25 bu/acre to achieve a plant population of 22-25 plants/ft2.

Circumstances requiring heavier seeding rates include large seed size, low germination, late seeding, abundant moisture, deep seeding, rough seed bed and high weed pressure.

Seeding Depth

1.5 to 2 inches. Deeper seeding results in weaker plants, reduced emergence, greater susceptibility to root rot and decreased yield.

Fertilizer Requirements For Barley

General

For specific recommendations, have your soil tested. If soil analyses are not available, a general recommendation is as follows:

| Nitrogen (N): | Apply 0-30 lb/acre N following fallow or legume breaking, 30-55 lb/acre N following grass and grass-legume breaking and 55-90 lb/acre N following stubble. The primary nitrogen deficiency symptom is leaf yellowing starting with the older leaves. If nitrogen deficiencies are visible in the field, loss in yield potential has already occurred. |

|---|---|

| Phosphate (P2O5): | Apply phosphate rates at 30-40 lb/acre. |

| Potassium (K2O): | On sandy-textured or organic soils, apply potassium rates of 15-30 lb/acre. |

| Sulphur (S): | Low sulphur levels can occur in any Manitoba soils. When required, apply 15 lb/acre of sulphate sulphur. The primary sulphur deficiency symptom is leaf yellowing, starting with the newest leaves. |

Special Considerations for Malting Barley

For barley to be accepted as malting grade, the grain should contain 11 to 12.5 per cent protein. Protein levels in barley are determined by the amount of available nitrogen plus growing season moisture and temperature conditions. High rates of nitrogen and/or limited growing-season moisture may result in protein content above the acceptable levels.

- Further information on Fertilizer use in Manitoba

- Nitrogen Rate Calculator for Wheat, Barley and Canola

Weed Control

Barley is a competitive crop that has the ability to choke out many weeds. Depending on the relative time of emergence and the weed density, herbicides may not be necessary, which improves net returns.

Refer to the Guide to Field Crop Protection.

Insects

Grasshoppers, aphids, cutworms, wireworms and armyworms can damage barley. A dual-purpose seed treatment that includes an insecticide should be used if wireworms are expected to be a problem.

Refer to the Guide to Field Crop Protection.

Diseases Affecting Barley

Barley fields should be monitored for leaf diseases on a regular basis during the growing season. Identify the disease and, if control is warranted, apply a registered fungicide to minimize yield loss. Timing of the fungicide application is critical, so read and follow label directions carefully.

Netted and spotted forms of net blotch and spot blotch are the most common barley foliar diseases in Manitoba. Fusarium head blight and ergot affect barley heads by reducing grain quality. For most barley diseases, control measures include seed treatment with appropriate fungicides, seeding resistant varieties, and crop rotation to non-host crops.

All forms of smuts can be controlled with the appropriate seed treatment.

Other diseases of interest in barley include stem rust, leaf rust, bacterial blight, septoria leaf and glume blotch, and barley yellow dwarf virus.

Refer to the Guide to Field Crop Protection.

Harvesting Barley

SwathingSwath when the heads have lost their green colour and have a moisture content below 30 percent. At 30 percent the barley kernel is firm but can be dented with your thumbnail. CombiningHulled BarleyTo minimize cracking and breakage, slow the cylinder speed, increase the concave clearance and maintain low volume in the return. For malting barley, check the sample for the presence of a bit of awn on the kernels to signal that the combine is doing a proper job of threshing. Awns of 1/8 to 1/4 inch left on the kernels are desired. |

|

Combining can begin at 18 percent to 20 percent if the grain is to be dried. Higher kernel moisture content may lead to storage problems. For malting barley, combining and handling below 13.5 percent may cause peeling. Natural air drying systems can be used to allow harvesting by straight combining or picking up swaths to begin at 16 percent moisture. Threshing malting or seed barley at a moisture content greater than 16 percent, then aerating, has led to disappointing results due to germination loss during storage.

Hulless Barley

For hulless barley, examine the threshed grain for cracking or the presence of adhering hulls above the grading limits (5 percent limit for human consumption, 15 percent limit for feed). A dehulling process may be required to reduce the percentage of hulls adhering to meet grade requirements.

Hulless barley should not be combined above 13.5 percent kernel moisture as it will be difficult to remove the hulls.

Storage

Malting barley at 13.5 percent moisture is desirable. Over 14.0 percent moisture does not store well and the quality and germination capacity may deteriorate. Ideal storage conditions can be maintained by means of natural aeration or frequent turning of the grain in the bin.

Feed barley should be stored at 14.5 percent or less kernel moisture.

- Grain Drying and Storage of Damp Grain

- Prevention and Control of Insects and Mites in Farm-Stored Grain

For further information, please contact your nearest Manitoba Agriculture office.